Welcome to Henan Global Heavy Industry Technology Co. , Ltd.

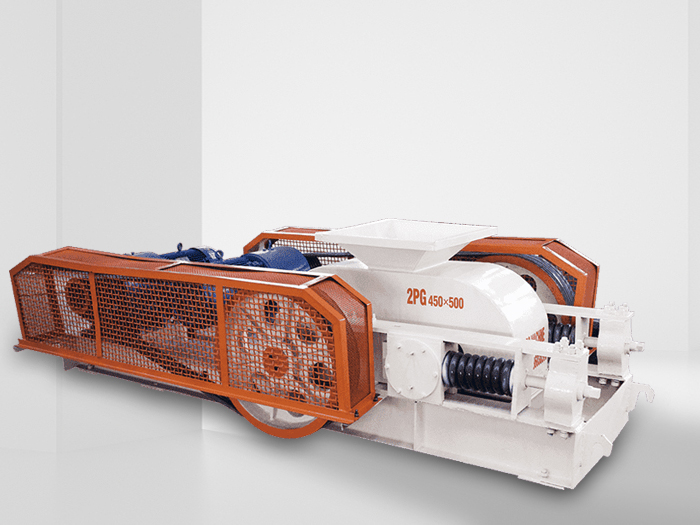

Roller crusher

Feed:≤130mm

Feed:≤130mm

Produce:5-125t/h

Produce:5-125t/h

Materials:Coal gangue, limestone, basalt, iron ore, quartzite, diabase, iron ore, gold ore, copper ore, etc.

- Preponderance:The roller crusher is suitable for crushing medium-hard materials, such as limestone, slag, coke, coal and other materials in the industrial sectors of cement, chemical industry, electric power, metallurgy, building materials, refractory materials, and fi

Introduction to Roller Crusher

The double-roller crusher is also called the double-roller sand making machine and double-roller crusher. It is suitable for crushing medium-hard materials in the industrial sectors of cement, chemical industry, electric power, metallurgy, building materials, refractory materials, etc. The double-roller crusher such as limestone, slag , Coke, coal and other materials in the crushing and fine crushing operations. The roller sand making machine has reliable operation, simple maintenance, low operating cost, and adjustable discharge granularity. The roller crusher is a machine that uses the friction force of the roller surface to bite the material into the crushing area, so that it can be crushed by crushing or splitting. When used for coarse crushing or to increase the crushing ratio, teeth or grooves are often made on the roller surface to increase the splitting effect.

Performance Advantages

Can be designed and manufactured according to the hardness of the material

It is used to crush special solid materials. It can be designed and manufactured according to the hardness of the material, that is, according to the material provided by the user, the pressure of the material is measured first, and then the parameters of the roller crusher are designed.

New design to avoid belt slippage

The movable roller and the fixed roller are connected to the power by a hard connection, that is, a coupling. The movable roller adopts universal joint technology, which avoids the defect of belt slippage of the old belt model (large material block).

Intelligent powder selection, increase rate

The feeder adopts a non-powered powder selection structure, that is, before the material enters the roller press, it passes through the non-powered powder selection device, and selects the material below 3-8mm without entering the roller press, only the coarse material is fed through the vibration feed The machine enters the roller press evenly and horizontally, which can improve the crushing efficiency.

Protection mechanism to avoid damage to the machine

In case of over-hard or unbreakable objects, the rollers can automatically retreat by the action of the spring, which increases the gap between the rollers and prevents over-hard or unbreakable objects from falling, thereby protecting the machine from damage.

Adjustable discharge and output

The double-roll crusher can control the discharging particle size by adjusting the gap between the rollers, thereby changing the output per hour.

Working principle of roller crusher

Roller crusher is a machine that uses the friction force of the roller surface to bite the material into the crushing area, so that it can be crushed by crushing or splitting. When it is used for coarse crushing or when the crushing ratio needs to be increased, teeth or grooves are often made on the roller surface to increase the splitting effect.

Technical parameter

| model | Roller diameter(mm) | Roller length(mm) | Feeding size(mm) | Discharge size(mm) | Production(t/h) | Number of rollers | Roller speed(r/min) | weight(t) | shape(mm) | Motor | power(kw) |

| 2PG400×250 | 400 | 250 | <25 | 2-8 | 5-10 | 2 | 180 | 1.1 | 1215×834×830 | Y160L-6 | 2×5.5 |

| 2PG450×500 | 450 | 500 | <100 | 6-60 | 20-55 | 2 | 64 | 3.8 | 2260×2200×766 | Y160L-8 | 2×11 |

| 2PG610×400 | 610 | 400 | <80 | 8-30 | 30-70 | 2 | 75 | 3.5 | 2235×1722×810 | Y225M-6 | 2×15 |

| 2PG700×400 | 700 | 400 | <100 | 5-30 | 30-100 | 2 | 95 | 7.8 | 4300×1200×1200 | Y200L-4 | 2×18.5 |

| 2PG600×800 | 600 | 800 | <130 | 8-125 | 60-125 | 2 | 50 | 8.34 | 2780×3065×1310 | Y225M-B | 2×22 |

| Model | Feeding size(mm) | Production capacity(t/h) |

| 2PG400×250 | <25 | 5-10 |

| 2PG450×500 | <100 | 20-55 |

| 2PG610×400 | <80 | 30-70 |

| 2PG700×400 | <100 | 30-100 |

| 2PG600×800 | <130 | 60-125 |

Related articles

Is there any movement in the large p

2021-07-08

"Pebble crushing is a common raw material in the sand and stone processing industry. Compared with the fixed crushing production line,

Reply

Equipment configuration and price of

2021-07-08

"Sand production line is the production of all kinds of stone, sand, aggregate production lines, from a number of equipment, commonly used sand production

Reply

Mobile crusher operation notes as we

2021-07-08

"Any object to long-term stable use is inseparable from maintenance, in the operation of the time also need to pay more attention, mobile crusher is no exception.

Reply

What are the types of crawler mobile

2021-07-08

"With the continuous progress of science and technology, China's industrial system has undergone a huge leap in development

Reply

Leave a Comment