Welcome to Henan Global Heavy Industry Technology Co. , Ltd.

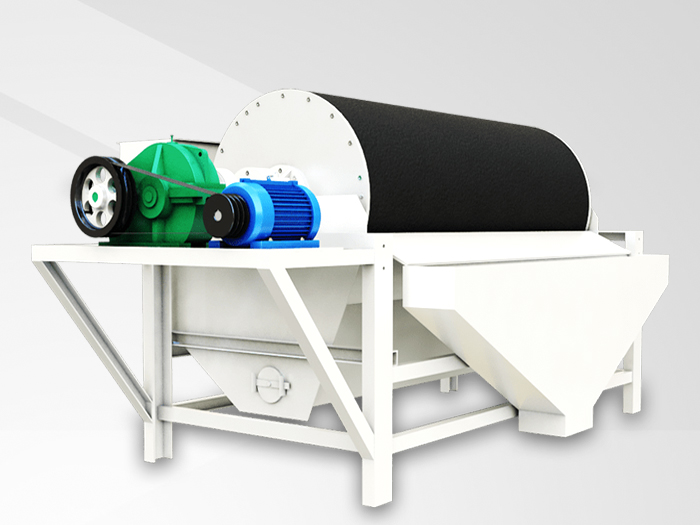

Magnetic separator

Feed size:≤3mm

Feed size:≤3mm

capacity:10-280t/h

capacity:10-280t/h

Materials:Suitable for materials such as magnetic iron ore, magnetic pyrite, roasted ore, non-metallic ore, etc. with a particle size of less than mm.

- Preponderance:Reasonable design, reliable operation, high magnetic separation efficiency and good energy saving effect.

Introduction of PC HAMMER crusher

The magnetic separator is a separation and screening equipment used to remove iron powder and separate substances with magnetic differences for the reuse of powdery particles. The system of the magnetic separator is made of high-quality ferrite material or composite rare earth magnet steel, with an average magnetic induction intensity of the cylinder surface of 10 to 600 mT, suitable for the wet magnetic separation of materials such as magnetite, pyrrhotite, roasted ore, and ilmenite with a size of less than 3 mm. It is also used for iron removal operations of coal, non-metallic ore, building materials, etc. It has the advantages of simple, large processing capacity, convenient operation, and easy maintenance. It is one of the widely used and highly universal machine species in the industry. Henan Global Heavy Industry can provide different of magnetic separators with different surface strengths, such as countercurrent, semi-countercurrent, and reverse current, according to user needs.

Performance Advantages

Optional, wide range of applications;

Magnetic separators can be divided into dry iron removers and wet iron removers according to the dry and wet selection methods; according to the different needs of, three different types of tank bodies can be provided: forward, reverse, and semi-reverse, to meet the application of different materials.

No blockage, large processing capacity

The magnetic separator adopts a wrapped open magnetic system, so the material does not clump and there is no blockage phenomenon, so the processing capacity is large and the processing capacity of a single rough selection machine can reach more than 50 tons of raw ore, and multiple machines can also work in series, which can greatly increase the.

Advanced process; reliable operation

Avoiding the wear and corrosion of the tank body, extending the service life of the magnetic separator; the magnetic separator bearings have high load-bearing capacity ensuring the magnetic separator operates without any faults, running smoothly and reliably.

High magnetic field strength

The magnetic system of the magnetic separator is made of high-quality ferrite material or composite rare earth magnet steel, with high magnetic induction strength and large field depth, and it is one of the widely used and highly universal models in the industry.

Working principle of hammer crusher

The magnetic separator mainly consists of six parts: drum, roller, brush roller, magnetic system, tank body and transmission part. When working, ore slurry flows into the tank body from the ore box, and the ore particles enter the ore feeding area of the tank body in a loose state under the water flow operation of ore feeding water pipe. Under the action of the magnetic field, the magnetic ore particles are magnetically aggregated to form "magnetic groups" or "magnetic chains". The "magnetic" or "magnetic chains" are subjected to magnetic force in the ore slurry and move towards the magnetic pole, and are adsorbed on the drum. Since the polar of the magnetic poles are alternately arranged along the direction of rotation of the drum and are fixed during operation, when the "magnetic groups" or "magnetic chains" rotate with the, the magnetic stirring phenomenon is generated due to the alternation of the magnetic poles, and the non-magnetic ore minerals such as gangue contained in the "magnetic groups" ormagnetic chains" fall off during turning, and the "magnetic groups" or "magnetic chains" adsorbed on the surface of the drum are the concentrate. The concentrate is discharged the concentrate tank under the action of the weakest magnetic force at the edge of the magnetic system as the drum rotates, and the ore is discharged by the brush roller if it a fully magnetic magnetic roller. Non-magnetic or weakly magnetic ore minerals are left in the ore slurry and discharged from the tank with the ore slurry, which is the tail.

Technical parameter

| Model | Tube diameter | Tube length | Speed(r/min) | Feed size | Capacity(t/h) | Power(kw) |

| CTB6012 | 600mm | 1200mm | <35 | 2-0mm | 10-20 | 1.5 |

| CTB6018 | 600mm | 1800mm | <35 | 2-0mm | 15-30 | 2.2 |

| CTB7518 | 750mm | 1800mm | <35 | 2-0mm | 20-45 | 2.2 |

| CTB9018 | 900mm | 1800mm | <35 | 3-0mm | 40-60 | 3 |

| CTB9021 | 900mm | 2100mm | <35 | 3-0mm | 45-60 | 3 |

| CTB9024 | 900mm | 2400mm | <28 | 3-0mm | 45-70 | 4 |

| CTB1018 | 1050mm | 1800mm | <20 | 3-0mm | 50-75 | 5.5 |

| CTB1021 | 1050mm | 2100mm | <20 | 3-0mm | 50-100 | 5.5 |

| CTB1024 | 1050mm | 2400mm | <20 | 3-0mm | 60-120 | 5.5 |

| CTB1218 | 1200mm | 1800mm | <18 | 3-0mm | 80-140 | 5.5 |

| CTB1224 | 1200mm | 2400mm | <18 | 3-0mm | 85-180 | 7.5 |

| CTB1230 | 1200mm | 3000mm | <18 | 3-0mm | 100-180 | 7.5 |

| CTB1530 | 1500mm | 3000mm | <14 | 3-0mm | 170-280 | 11 |

Related articles

Is there any movement in the large p

2021-07-08

"Pebble crushing is a common raw material in the sand and stone processing industry. Compared with the fixed crushing production line,

Reply

Equipment configuration and price of

2021-07-08

"Sand production line is the production of all kinds of stone, sand, aggregate production lines, from a number of equipment, commonly used sand production

Reply

Mobile crusher operation notes as we

2021-07-08

"Any object to long-term stable use is inseparable from maintenance, in the operation of the time also need to pay more attention, mobile crusher is no exception.

Reply

What are the types of crawler mobile

2021-07-08

"With the continuous progress of science and technology, China's industrial system has undergone a huge leap in development

Reply

Leave a Comment