Welcome to Henan Global Heavy Industry Technology Co. , Ltd.

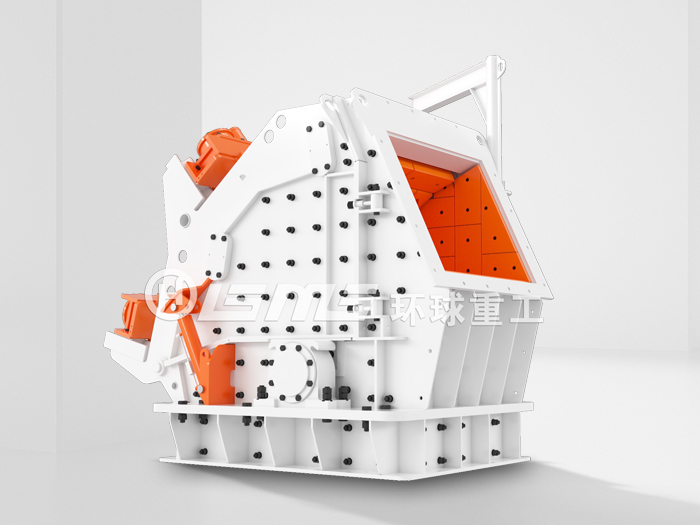

Large-diameter impact crusher

Feed:<1050mm

Feed:<1050mm

Produce:100-500t/h

Produce:100-500t/h

Materials:Granite, limestone, cobblestone, iron ore and other compressive strength of not more than 300 MPA of rock.

- Preponderance:As the basic principle of the general impact crusher, the LF large-caliber impact crusher can crush larger pieces of ore, with a maximum feed size of 1050x1700mm, large feed, fine particle shape after crushing.

Introduction of LF LARGE-CALIBER IMPACT crusher

LF large-diameter impact crusher and ordinary impact crusher the main difference between the feeding mouth, large-diameter impact crusher feeding mouth widening, can break larger stones, crushing efficiency has been improved. Widely used in building materials, ore crushing, transportation, energy, chemical and other industries used to fine materials, the size of the discharge particles can be adjusted, crushing specifications diversification.

Performance Advantages

Wide Adjustment Range and various crushing specifications

LF large-caliber impact crusher with large feeding, crushing ratio, adjustable discharge particle size and diversified discharge specifications.

Energy-saving, stable operation

The design of large crushing chamber of large-mouth impact crusher has the advantages of high production efficiency, stable operation, high energy-saving and high yield.

Easy to wear parts wear small, long service life

The Abrasion of the hammer only occurs on the side facing the material. When the rotor rotates, the material will fall to the surface of the Hammer. The back and side of the hammer are not abraded, even the side facing the material is little abraded.

Simple structure, easy to maintain

LF LARGE-CALIBER IMPACT crusher structure design is very simple, easy to crush stone, also convenient for later maintenance and repair.

LF large-caliber impact crusher is the "Stone Iron" crushing principle, the motor drives the rotor to rotate, the rotor drives the plate hammer on the rotor to rotate, the stone enters the crushing chamber of the impact crusher and is broken by the high-speed rotating plate Hammer, the huge impact force causes the stone material to collide with the counter-strike lining board, and then the stone material is bounced back by the counter-strike Lining Board to the plate hammer crushing zone. After repeated impact crushing, impact crushing, friction crushing, and finally the stone material which conforms to the size of the discharged material particle is discharged from the discharge hole to the crushing chamber, do Not meet the requirements of the size of the larger stone particles continue to be broken, until the finished product can be discharged.

Technical parameter

| Types | Feed port(mm) | Maximum feed side length(mm) | Deal with(t/h) | Power(kw) | Weight(kg) |

| LF150 | 820X980 | 100-200 | 100-200 | 90-200 | 12000 |

| LF250 | 960X1360 | 200-400 | 200-400 | 180-250 | 17000 |

| LF350 | 1050X1700 | 300-500 | 300-500 | 200-400 | 24000 |

| Model | Inlet(mm) | Processing power(t/h) |

| LF150 | 820X980 | 100-200 |

| LF250 | 960X1360 | 200-400 |

| LF350 | 1050X1700 | 300-500 |

Related articles

Is there any movement in the large p

2021-07-08

"Pebble crushing is a common raw material in the sand and stone processing industry. Compared with the fixed crushing production line,

Reply

Equipment configuration and price of

2021-07-08

"Sand production line is the production of all kinds of stone, sand, aggregate production lines, from a number of equipment, commonly used sand production

Reply

Mobile crusher operation notes as we

2021-07-08

"Any object to long-term stable use is inseparable from maintenance, in the operation of the time also need to pay more attention, mobile crusher is no exception.

Reply

What are the types of crawler mobile

2021-07-08

"With the continuous progress of science and technology, China's industrial system has undergone a huge leap in development

Reply

Leave a Comment