Welcome to Henan Global Heavy Industry Technology Co. , Ltd.

Introduction of PC HAMMER crusher

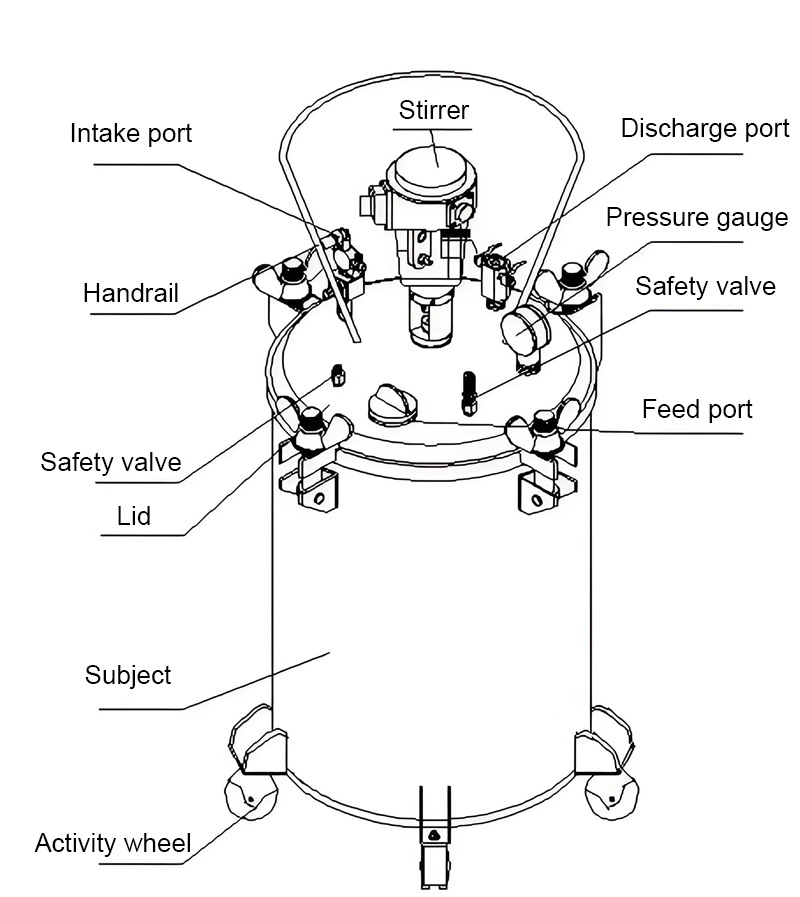

The agitator is composed of tank body, motor, fixed frame, coupling, reducer, belt, beam bracket, stirring impeller and other parts. agitator is mainly used for stirring before flotation. The motor transmits the triangle belt to drive the impeller to rotate. The agitator fully mixes the medicine the pulp, and evenly mixes them. It is an essential equipment to increase the reaction time of the agent and strengthen the reaction quality of the agent.

Performance Advantages

Advanced technology; stable quality

The whole machine is composed of advanced technology and unique structure, which makes it have the characteristics of advanced equipment performance, stable finished product quality, uniform mixing and rapid.

Compact structure and good sealing performance

The mixing drum is designed to be compact and the internal structure clearance is too small. It is not easy to enter dust during operation. A dust-proof plate is at the feed port to effectively prevent the backflow of mist and the entry of sundries and dust.

Stir well

The stirring blade adopts a fan-shaped design, which increases the contact area with the medium during stirring, thus achieving uniform stirring of the material.

Convenient water volume adjustment

The nozzle of the mixing drum is set in multiple rows, with uniform and adjustable water flow, which is convenient and time-saving.

Working principle of hammer crusher

The mixing tank is driven by the motor through a triangular belt to rotate the impeller. Add water and necessary reagents to the ore during or after grinding and adjust it into pulp in the mixing tank. Then inject the starting pulp into the pulp tank, and introduce air into the pulp to form a large number of bubbles. Some mineral that are not easily wetted by water, that is, generally called hydrophobic, adhere to the bubbles and float to the surface of the pulp with the bubbles to form aized foam layer. Some mineral particles that are easily wetted by water, that is, generally called hydrophilic, do not adhere to the bubbles, but remain in the pulp The mineralized foam containing specific minerals is discharged, thus achieving the purpose of ore dressing.

Technical parameter

| Model | Slot body size | Effective volume (m³) |

Speed | Motor power (kw) |

Dimensions (L×W×H)(mm) |

Weight(kg) | |

| Diameter | Height | ||||||

| XB-10×10 | 1000mm | 1000mm | 0.58 | 390 | 1.5 | 1130×1130×1521 | 1050 |

| XB-12×12 | 1200mm | 1200mm | 1.18 | 390 | 2.2 | 1130×1330×1721 | 1160 |

| XB-15×15 | 1500mm | 1500mm | 2.2 | 280 | 3 | 1750×1640×2190 | 1270 |

| XB-20×20 | 2000mm | 2000mm | 5.6 | 210 | 5.5 | 2380×2160×2850 | 1700 |

| XB-25×25 | 2500mm | 2500mm | 11.2 | 190 | 7.5 | 2990×2720×3540 | 3500 |

| XB-30×30 | 3000mm | 3000mm | 19 | 140 | 18.5 | 4030×3270×3010 | 5200 |

| XB-35×35 | 3500mm | 3500mm | 29 | 230 | 30 | 3920×3740×4970 | 6630 |

| XB-40×40 | 4000mm | 4000mm | 45 | 210 | 37 | 4520×4320×5570 | 7830 |

| XBT-10×15 | 1000mm | 1500mm | 1 | 510 | 2.2 | 1130×1130×2070 | 1250 |

| XBT-15×20 | 1500mm | 2000mm | 2.9 | 400 | 4 | 1636×1768×2785 | 1677 |

| XBT-20×20 | 2000mm | 2000mm | 5.6 | 312 | 11 | 2180×2220×3015 | 3100 |

| XF-20×20 | 2000mm | 2000mm | 7.07 | 82.5 | 1.5 | 2032×2032×3595 | 2400 |

| XF-25×30 | 2500mm | 3000mm | 13.5 | 57.6 | 2.2 | 2532×2532×4152 | 3670 |

| XF-30×30 | 3000mm | 3000mm | 22.97 | 50 | 2.2 | 3180×3180×4673 | 5340 |

| XF-35×40 | 3500mm | 4000mm | 35.6 | 41 | 4 | 3685×3685×5314 | 7140 |

| XF-40×45 | 4000mm | 4500mm | 52.78 | 33.5 | 4 | 4185×4185×5814 | 9300 |

| XF-45×50 | 4500mm | 5000mm | 74.75 | 33.5 | 5.5 | 4685×4685×6466 | 10500 |

| XF-50×56 | 5000mm | 5600mm | 102.1 | 30.6 | 5.5 | 5185×5185×6975 | 12300 |

| XF-55×60 | 5500mm | 6000mm | 135.4 | 24.4 | 7.5 | 5670×5670×756 | 13500 |

Related articles

Is there any movement in the large p

2021-07-08

"Pebble crushing is a common raw material in the sand and stone processing industry. Compared with the fixed crushing production line,

Reply

Equipment configuration and price of

2021-07-08

"Sand production line is the production of all kinds of stone, sand, aggregate production lines, from a number of equipment, commonly used sand production

Reply

Mobile crusher operation notes as we

2021-07-08

"Any object to long-term stable use is inseparable from maintenance, in the operation of the time also need to pay more attention, mobile crusher is no exception.

Reply

What are the types of crawler mobile

2021-07-08

"With the continuous progress of science and technology, China's industrial system has undergone a huge leap in development

Reply

Leave a Comment