Thank you for your interests in Global Heavy Industry.Please email to submit your inquiry information to us.

Belt Conveyor Operation Manual

Zhengzhou Huanqiu Heavy Industries Ltd.

July 12, 2011

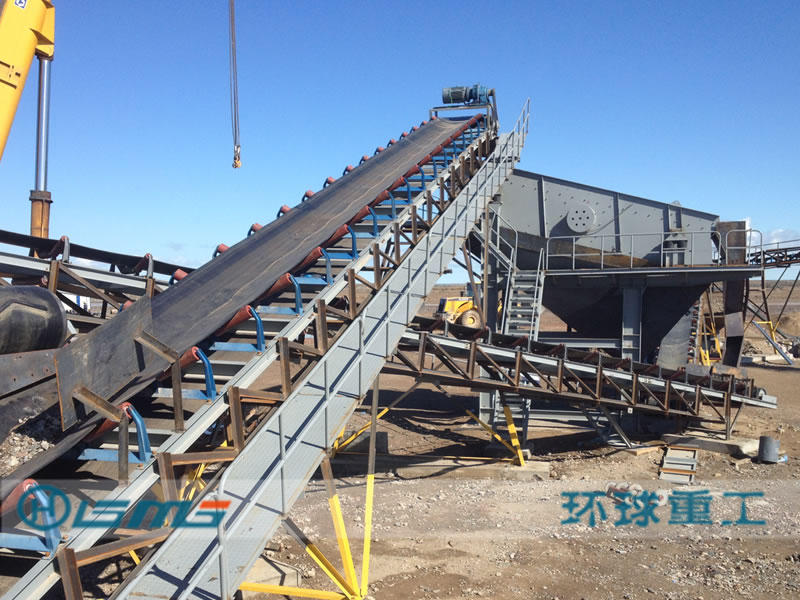

Display Photo

Ⅰ. Product Overview

Belt conveyor is a continuous conveyor with a closed ring conveyor belt as driving and bearing component which is bypassed and tensioned on the front and rear drum, and the conveying task will be accomplished through the continuous motion of the conveyor belt. It is able to convey materials in large quantity at horizontal direction or a direction with slight inclination, which significantly improves the production efficiency, reduces production cost and labor intensity of workers. With such advantages as large conveying capacity, long conveying distance, convenient operation and maintenance, steady and reliable running, no damage of materials to be conveyed, small frictional resistance, no noise and low power consumption, it is an economic conveying equipment for conveying light materials and is widely used in electronic, electrical equipment, food, chemical and tobacco industries.

Ⅱ. Scope of Application and Working Conditions

This product is applicable to the environment where the temperature is between -25ºc and +40 ºc, the humidity is not more than 85%, the elevation is not more than 1000m, the and there is no fire, explosion hazard or corrosive medium. The power supply shall be of 3 phases, 50HZ and 380V.

Ⅳ. Exterior Structure

Ⅴ. Operation Specifications and Maintenance

1. Check the power supply before each startup. Check whether the indication light is in normal condition, and the next operation can be carried out after making sure that there is no hidden danger.

2. The operators shall have general mechanical and electronic knowledge and are in good health, and they shall also master the characters of service and security specifications of this belt conveyor.

3. Safety check shall be carried out before each startup.

4. Immediately stop the machine when any component scratch the belt and check the reason.

5. Effective measures shall be taken to prevent foreign matters entering into the belt, otherwise, the foreign matters may stick to or seize the belt or make the belt skid, which will reduce the conveying efficiency.

6. Routine maintenance shall be made every three months.

6.1 Remove the dirt oil stains on the surface.

6.2 Check whether all parts are connected well and whether the any connecting screw is loose.

6.3 Carefully remove the dirt on the internal side of the belt to ensure reliable belt friction.

7. Matter needing attention during maintenance inspection

7.1 The power shall be turned off during maintenance inspection.

7.2 It is not allowed to unplug or take down the internal cable and wire or make them unmatched, otherwise, the converter may be damaged.

7.3 The power input terminal shall be in correct position during installation (pay attention to the power line and motor line)

7.4 It is not allowed to leave such accessories as screw in the converter during installation to avoid short circuit.

7.5 Keep the converter clean after installation to keep dust, oil gas or wet gas out.

8. Routine check items

8.1 Whether the power voltage accords with the voltage required by the converter. (Pay special attention to whether the power line or motor line is damaged.)

8.2 Whether the wiring terminal or connector is loosening. (Whether there is broken strand in the power supply wire or terminal.)

8.3 Where there is dust or corrosive liquid in the converter.

8.4 It is not allowed to measure insulation resistance.

8.5 Check the output voltage, output current and output frequency of the converter (Any of them cannot be far from standard.)

8.6 Whether the temperature is between -10-45 ºc and whether the installation environment is well ventilated.

8.7 Humidity shall be kept under 90% to prevent water vapor from condensing.

8.8 Where there is abnormal noise or abnormal vibration during running.

8.9 The ventilation opening shall be cleaned frequently.