Applications:Cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic mineral, construction material, ceramics.

Materials:calcite, marble, limestone, coarse whiting, talc, barite and dolomite and so on.

Feed size:50mm

Capacity:30~250 t/h

Vertical grinding mill is the newest grinding machine, which integrates the advanced international technology and years of mill-producing experience . It is an ideal equipment that integrates crushing, drying, grinding and grading conveyor all together.

Vertical grinding machine can be widely used in cement making, power , metallurgy, chemical and non- metalliferous ore industries. It is used to grind lumpy, granular and powdery materials to the required size.

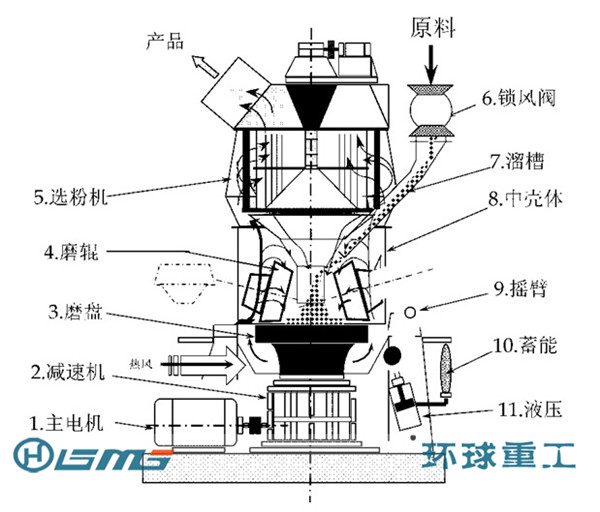

Vertical mill has two pairs of grinding rollers, each pair of roller composed of two narrow rollers, mounted on the same axis and can rotate at different speeds. There are two circular disc slot, and roller to the tire shape, work pressure in the tank. Disc roller and the relative sliding velocity between small and roller can swing, even if the roller sleeve and the disc after the liner wear can guarantee a good abrasive, will not affect the grinding effect. Roller symmetrical structure, one side can be upside down after use and wear. Material grinding process: hydraulic pneumatic roller device through the pressure applied to the material on the crushing of materials, the materials have been moved to crush the edge of disc, from the disc around the nozzle from the exhaust air to improve these materials to Separator.Meal to separate returns after a concentrated mill, fine powder was collected in the precipitator unloading. In the gas flow is small, the meal can not be increased to enhance air flow, they would fall through the nozzle discharged outside the mill, bucket elevator to be transported to the feeder of vertical mill and was re-grinding mill feed people.

1. Low Investment Cost. This mill itself can crush, dry, grinding, classifying, so the system is simple, and occupation area is about 50% of ball mill system. In addition, it can be installed outside, so it will reduce a large number of investment costs.

2. Low Operation Cost. ⑴ High efficiency: roller compacted materials directly onto the grinding disc, so power consumption is low. Compared with ball mill, it saves energy consumption by 30% ~ 40%. ⑵ Less wear and tear: As the roller is not in direct contact with the disc, and material of the roller and liner is high quality, so life lime is long.

3. High Drying Ability. As the hot air inside contacts directly with the material, drying ability is higher, and it saves energy. By regulating the air temperature, it can meet requirements with different humidity.

4. Simple and reliable operation. ⑴ It is equipped with automatic control systems, so remote control makes it easy to operate. ⑵ It is equipped with one device,which prevents the roller from contacting with the liner directly, and avoids the destructive impact and severe vibration.

5. The stability of product quality. As the material stays in the mill for a short time, it is easy to detect and control the product particle size and chemical composition, to reduce duplication of milling, stable product quality.

6. Maintenance convenience. By repairing fuel tank, rotating the arm, it is fast to replace the roller sleeve, and liner, and reduce the downtime loss.

7. Environmental protection. It is with small vibration, low noise, and the overall sealing. The system works under negative pressure, so there is no dust going out. It meets the requirements of the state Environmental Protection.

Global Heavy Industry provides customers with production line design process and helps to design a satisfactory and reasonable production line. We also provide related technical personnel training and enable them to acquire a certain amount of technical knowledge and machine maintenance tips.

| Series | Ore Mill | |||||||||

| Model | LM130K | LM150K | LM170K | LM190K | LM220K | LM240K | LM280K | LM340K | LM370K | |

| Disc Dia. (mm) | 1300 | 1500 | 1700 | 1900 | 2200 | 2400 | 2800 | 3400 | 3700 | |

| Capacity (t/h) | 10~30 | 13~40 | 18~57 | 23~72 | 36~114 | 41~128 | 50~196 | 70~260 | 90~320 | |

| Output fineness | micron | 170~45 | 170~45 | 170~45 | 170~45 | 170~45 | 170~45 | 170~45 | 170~45 | 170~45 |

| mesh | 80~325 | 80~325 | 80~325 | 80~325 | 80~325 | 80~325 | 80~325 | 80~325 | 80~325 | |

| Product moisture | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | |

| Max.input size (mm) | <38 | <40 | <42 | <45 | <50 | <55 | <58 | <62 | <65 | |

| Best input moistrure | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | |

| input moistrure(drying required) | 4~15% | 4~15% | 4~15% | 4~15% | 4~15% | 4~15% | 4~15% | 4~15% | 4~15% | |

| Inlet air temperature (℃) | <350 | <350 | <350 | <350 | <350 | <350 | <350 | <350 | <350 | |

| Outlet air temperature (℃) | 70~95 | 70~95 | 70~95 | 70~95 | 70~95 | 70~95 | 70~95 | 70~95 | 70~95 | |

| Power (KW) | 185~220 | 250~280 | 355~400 | 450~500 | 710~800 | 800~900 | 1120 | 1800 | 2240 | |

Models and specifications of the equipment, according to the actual needs of customers, or special requirements of customers, can be custom designed.